The Challenge

It was similar challenge what every manufacturing industry faces during their initiation. AV Organics relied on paper, excel sheets, where the chances of human error in data entry, calculations and reporting were high. It was very time consuming to manual updates for production schedules, inventory records and order tracking slow down process cause delays.

- Limited insight: Without real-time data, manufacturers may struggle to track inventory levels, machine performance, or production status accurately.

- Delayed decisions: Managers cannot make quick, informed decisions, leading to bottlenecks or under-utilized resources.

Solutions

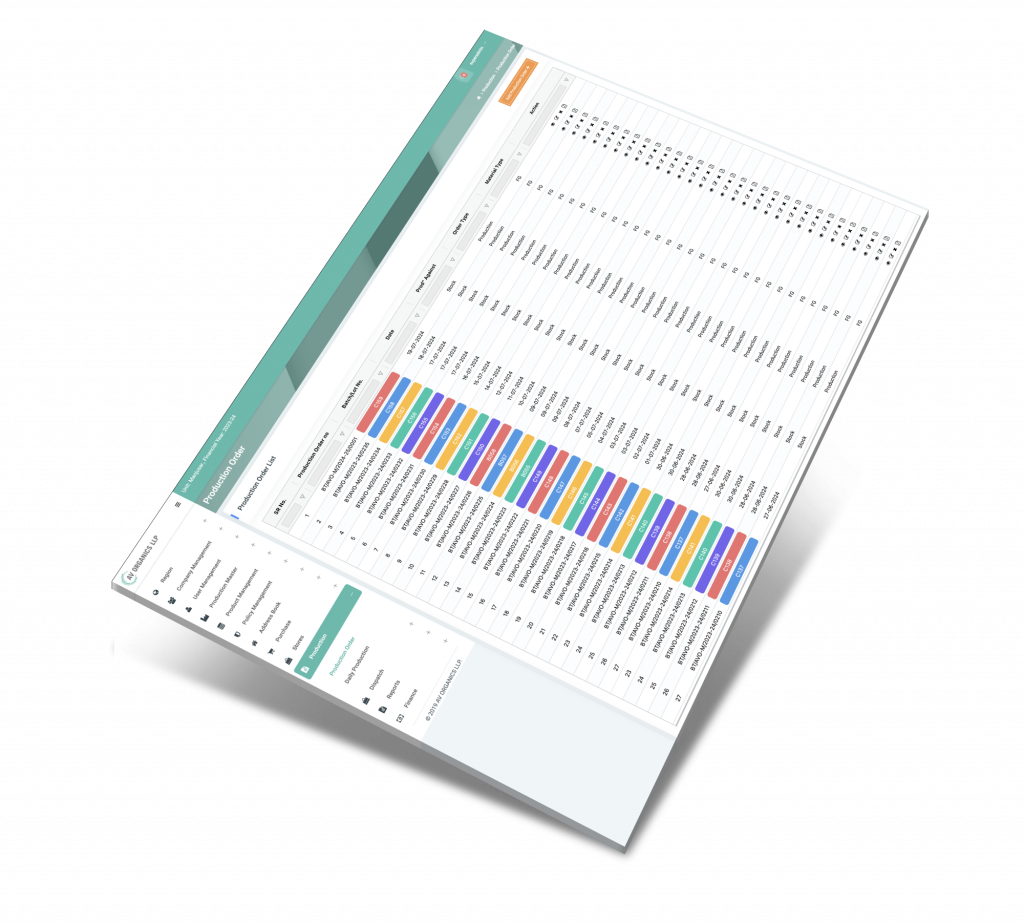

- Procurement Management allowed to manage their purchases and gave them a better control on validations and approvals.

- Stock & Inventory were updated on the go and there was minimal ambiguity is stock and inventory reports

- Production disruption due to lack of inventory, raw material management was eradicated.

- Real time data allowed them to manage their productions helping decision makers to take a quick action

- Production planning generating detailed reports on production efficiency, costs, and profitability was real time allowing data driven decisions..

With more than 18 years of experience in Production Planning and ERP, Proses is known for providing the best ERP software for manufacturing in India. We developed a simplified and user-friendly web application covering the majority of AV Organics’ production planning processes. Proses also provided dashboards and analytical reports to help manage their production line and stock for raw materials and finished goods. Deployed and implemented in 2019, the solution continues to benefit AV Organics, showcasing Proses’ expertise in delivering tailored ERP solutions for manufacturers.

The Proses team thoroughly understands our current business processes. They also suggested methods by which we could improve our processes. These guys knew their job inside-out. We were provided with a clear implementation schedule. Their team was constantly in touch with us and this made the process very easy. .

Aakash Vaghela

At our company, we specialize in providing comprehensive neural network services that can revolutionize your business. Whether you’re looking to enhance your data analysis capabilities, automate repetitive tasks, improve customer engagement, or optimize operational processes, our team of experts is here to help you leverage the full potential of neural networks.

Data lies at the heart of neural networks, and our services start with understanding your unique data landscape. We work closely with you to identify and collect relevant data sources, ensuring that your neural network models are built on a solid foundation. Our data scientists employ cutting-edge techniques to preprocess and clean the data, making it ready for training the neural network models.

Key Outcomes

Being a new manufacturing unit it always struggles with new challenges, with our production planning they were able to overcome majority of the challenges and were able to quickly identify the problems with the use of the data and overcome it in a right direction with a quick turnaround time.

- Realtime Data for quick decision

- Monitoring & Control on Stock and Inventory

- Efficient Production Scheduling

- Simplified supply chain management

- Optimized Operational Cost

Stock & Inventory

get in touchWe are always ready to help you and answer your questions

Reach out to us today to discover how our innovative technology solutions can transform your business.